My Squeeze – Silicone food pouch

When we were approached by Tracey, a local mum with a great solution to an everyday problem, we were able to help define the product she wanted to produce.

She had found that the available products for storing soft, pureed food for kids and infants were inconvenient, uncomfortable and environmentally unsuitable.

We set about looking at what important features would be required of her product, what should it look like to make it appealing to other mums and kids and what materials can be used to make it “mouth and spoon friendly”.

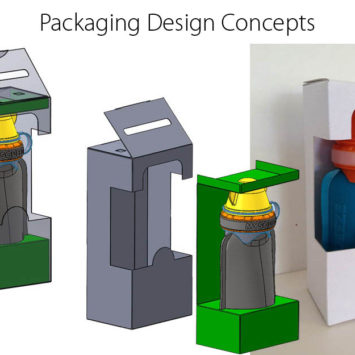

We created a number of concept designs from sketches and images samples of existing products. The concept designs were done quickly and easily using fast CAD modelling tools. These CAD files are great for visualisation and quick manipulation of shape, form and color.

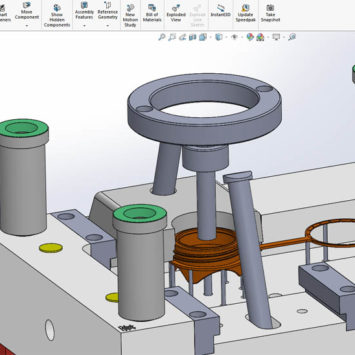

Once we were happy with the design features, the concept design was converted to a detailed CAD model for manufacturing purposes. With these files we were able to produce prototypes of the plastic and silicone parts, to test form, fit and function. As usual, several iterations of prototype were needed before we were 100% confident that the design would work.

(Click to enlarge)

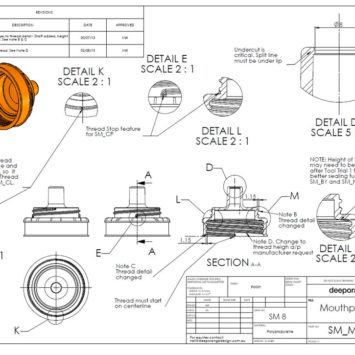

We could then produce a full manufacturing specification, including detailed engineering drawings, BPA free food grade plastic and silicone specifications and colours. In addition we could liaise with the manufacture to ensure the moulds and process were up to scratch and produce a number of trial production runs before mass production commenced.

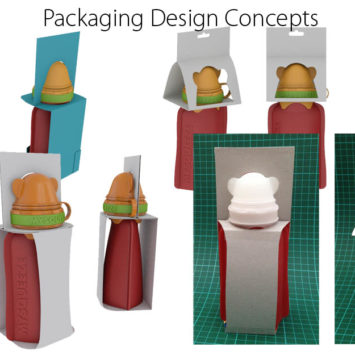

We also designed a custom packaging solution that allows the consumer to see and touch the actual product, and produced numerous 3D rendered images from the CAD files, to be used as marketing material.

The same CAD files were also used to produce drawings for Design Registration to be filed by a patent attorney.

My Squeeze is now sold in a number of retail outlets and online and has won awards and accolades.