You are probably here because you have a great product idea, or you want to improve an existing product.

Awesome! You have come to the right place. We help people develop new product, build and test prototypes and then prepare them for manufacturing or licensing.

Like most people, you probably have a pile of questions about designing products, so we have collected a few of the most common ones we get.

CLICK BELOW TO SEE THE ANSWERS:

My invention is my secret!

Yes, but in order for us to help you, we need to know what it is. We will never, ever steal someone else’s idea. We have enough of our own ideas on the table and we would not have remained in business for the last 15 years if we did!

However, if you prefer, we will happily sign a Non Disclosure Agreement so you can feel comfortable knowing that we will not share your information or data with anyone unless you agree.

Download a free NDA from here. Fill out the details and email it to us, we will sign and return it to you for your records. If you have your own short NDA and we don’t need a lawyer to decipher it, we are usually happy with that too.

What do I get from the FREE evaluation?

Generally, we will discuss your product over the phone. If you can provide photos, drawings or CAD files for reference, we can do this over email. The more information you provide, the more value we can give you for free.

You will get our expert opinion on:

- Whether we are the right people to help you.

- The process we would apply developing your product

- The general cost of design and manufacturing and timeframes

- Self-manufacturing vs licencing/royalties

- Patenting and design registration

Often, this conversation is enough to get started and we can determine from here if we simply need you to send us more information or samples or if we should schedule another free call.

We have many interstate and international clients that we have never met face to face! As long as we can communicate efficiently, we can work together productively.

Can we meet to discuss my idea in person?

Yes of course!

Once we have had an initial “discovery” conversation on the phone and have decided that we are a good fit for your project, we can meet in person to go into more detail. We cannot meet unless we have an idea what your product is as there are some things we can’t do and some things we won’t do!

We do charge a nominal fee of $150+GST for our time to discuss your idea in person, and you can pick our brains to your hearts content with no further obligation.

Our office is in a private residence, so we will generally meet for a coffee somewhere convenient for both of us.

We can discuss the product in much greater depth and detail and will be able to make suggestions or recommendations regarding:

- Design

- Technology

- Materials

- Prototyping processes

- Manufacturing

- Patents and Intellectual Property

- Commercialisation process

Once we have started a project, there is no charge for face to face meetings, but you may have to treat us to the coffee!

I want to go ahead, what's the (Project) Plan?

Firstly, we need a plan. Design is a dynamic process, so its important to have clear, defined targets and outcomes, otherwise we end up shooting in the dark and paying for stuff we don’t want or need.

A Project Plan also serves as a Service Agreement, which is our “contract” to design your product according to a process that we have agreed on in advance. The Plan defines Steps and Stages that have specific outcomes, deliverables and costs.

This way you know in advance what you should be getting at the end of each Stage, what it should cost and how long it should take.

Payments are made for each Stage as they progress and there are no surprises or hidden costs at the end. So, if you are not happy with the outcome of a particular stage, you are not obligated to continue with the next.

The cost to prepare a tailored Design Plan for your product is generally $150+GST

What is included in the Project Plan?

A Project is generally broken down into three main stages. Each of these will usually have a number of steps that we follow in order to produce a defined outcome or deliverable that is crucial for advancing to the next stage.

Each Project Plan is tailored specifically to the individual product. No two Plans are alike!

The stages generally include:

Stage 1 – Concept Development: Here we explore, investigate and develop the idea to determine the best approach. We design or refine the product to produce a final conceptual design that can be prototyped and tested.

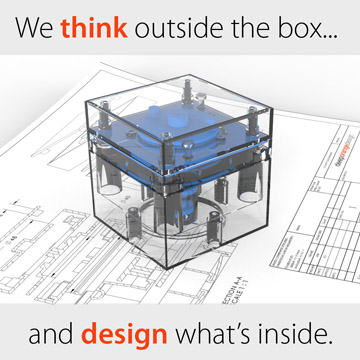

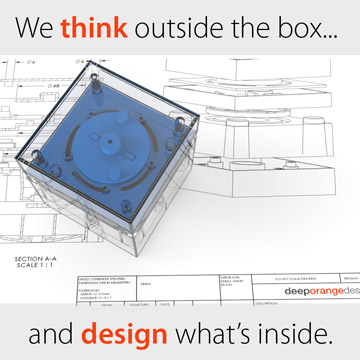

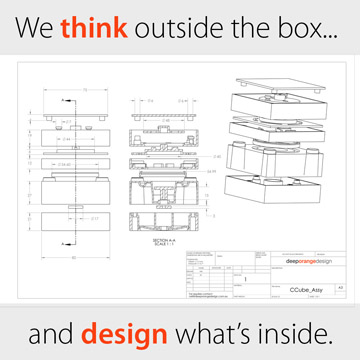

Stage 2 – Proof of Concept: Proving that the concept will work is essential. Building and testing prototypes is the only way to know for sure if the design will do what we want it to. This usually involves creating CAD files for 3D printing or CNC milling of parts, “hacking” of existing products or sourcing parts off the shelf. Generally, several iterations of the design are needed before a final proven concept is achieved.

Stage 3 – Preparation for commercialisation: For a product to turn a profit, it is crucial to know what is involved in manufacturing the product. For this we can prepare a full specification document with all the required instructions, engineering drawings, 3d CAD files and assembly jigs that would be needed for a manufacturer to provide accurate quotes. We can also prepare presentation material to show potential investors or licensees what the product would look like and how it would work, with ballpark manufacturing and production costs.

How much does it cost?

Well, gee, how long is a piece of string? Every project is different, and every job is quoted to a tailored Design Plan.

A cheap and simple $2 plastic product can often take many design hours to develop and require many iterations of test prototypes before it is ready for production.

Design costs can vary from a few hundred dollars to tens of thousands, depending on complexity, number of components and materials. Prototyping a single cheap and simple plastic part can cost a few dollars to hundreds of dollars, while complex multi-part assemblies can be thousands.

Manufacturing that same simple $2 plastic product can be prohibitively expensive to set up. Parts are only cheap when manufactured in large volume and making moulds for large volumes is certainly not cheap! So, unless you have manufacturing experience, a sound commercialisation strategy is highly recommended.

That said, in order to provide a quote for your project, we really need to discuss the product in detail and develop a Design Plan.

When we prepare the Project Plan, we can usually give a fixed quote for the first Stage, and ballpark estimates for the subsequent Stages. We are usually pretty spot on with our estimates… we’ve been doing this for a while 🙂 . We will also recommend a budget to allow for cost of prototyping or other services that may be needed.

Do I always need a Project Plan?

No.

The Project Plan is generally best for projects that need to follow a creative process to achieve an outcome.

If you need a simple (or complex) design modification, part fabrication or other non inventive process task, we can quote on the job for a fixed fee or an hourly rate.

For example, you if need to change the CAD for a part that you are manufacturing, or want to produce a small batch of a particular part.

Should I get a patent first?

Sorry, we cant answer that. We are designers, not patent attorneys 🙂

But we can say, from experience, that frequently the patentable novelty of a product is in the “how” it does what it does, not only the “what” it does. Often this “how” is only developed during the design process. So applying for a patent too early could mean that you miss out on protecting vital parts of your invention.

For example (from real life), we developed a system that performs a certain function that was new and novel. When the idea for this system was copied by a competitor, the patent on the unique shape of one of the components saved the day and the competitor had to pull their products from the shelves. The system’s novel function itself was too broad to be protected.

Do you do CAD and 3D printing?

Yes. 3D printing is just one of the tools we use to make and tests parts. We also use CNC mills, hand tools and even clay, cardboard and sticky tape when appropriate!

CAD is part and parcel of any three dimensional design job. We use Solidworks for most of our technical work, as well as other tools such as 3DSMax for design conceptualising and animation and Keyshot for rendering.

Can I licence my idea to some one else?

Yes you can!

In fact licencing is probably the best way to commercialise your first invention (or every invention!).

It involves letting another company take on the burden and risk of manufacturing, marketing and sales in exchange for a share of the profits. Usually the inventor will get around 3%-10% of the profits, but they wont have to fund the hefty manufacturing costs or worry about sales and marketing.

Read more about this here.

I have more questions!

Of course you do! And we can help 🙂

Give us a call or send a message here. No cost, no obligation.